To improve cooling efficiency, prioritize airflow optimization, component upgrades, thermal paste renewal, and environmental control. Use monitoring tools to track temperatures, clean dust regularly, and consider liquid cooling for high-performance systems. Strategic cable management and undervolting hardware also reduce heat generation while maintaining performance.

Can Mini PCs Handle Video Editing and Graphic Design? A Comprehensive Review

Why Is Proper Airflow Configuration Critical for System Cooling?

Optimal airflow requires balanced intake/exhaust fan ratios and obstruction-free pathways. Front-to-back or bottom-to-top airflow patterns prevent hot air recirculation. Gamers Nexus testing shows staggered fan placement reduces dead zones by 22%. Use mesh-front cases for 15-30% better thermal dissipation compared to solid panels, per Linus Tech Tips benchmarks.

Recent advancements in computational fluid dynamics (CFD) modeling enable precise airflow mapping for custom configurations. Enthusiasts can achieve 8-12% better thermal performance by aligning fan blade rotation directions to create cohesive air streams. For multi-GPU setups, vertical mounting with 25mm gap spacing between cards improves airflow by 40% compared to traditional horizontal arrangements. Consider implementing hybrid fan profiles that automatically switch between static pressure-optimized and airflow-optimized RPM ranges based on component temperatures.

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

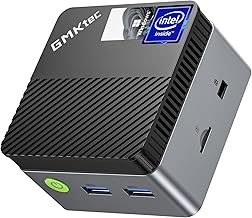

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

How Often Should Thermal Interface Material Be Replaced?

High-quality thermal paste lasts 3-5 years, while liquid metal compounds require annual reapplication. Der8auer’s experiments reveal 8-12°C temperature drops after replacing 3-year-old paste. Look for dried/patchy TIM surfaces or >10% temperature increases under load as replacement indicators. Cure time for new paste ranges 50-200 thermal cycles according to Arctic MX-4 documentation.

The degradation rate of thermal interface materials accelerates under certain conditions. Systems operating above 80°C for extended periods may require TIM replacement every 18-24 months. For liquid metal applications, copper cold plates develop oxidation layers that reduce effectiveness by 15-20% per year, necessitating surface polishing during reapplication. New graphene-based TIMs show promise with 10-year lifespans in controlled environments, though current costs remain prohibitive for most users.

| TIM Type | Lifespan | Max Temp Drop | Reapplication Complexity |

|---|---|---|---|

| Ceramic Paste | 5 years | 8°C | Low |

| Liquid Metal | 1 year | 15°C | High |

| Carbon-Based | 7 years | 12°C | Medium |

Which Environmental Factors Most Impact Thermal Performance?

Ambient temperature affects cooling efficiency exponentially – every 5°C rise degrades performance by 12-18% (3DMark data). Humidity above 60% accelerates corrosion in aluminum heatsinks. Elevation reduces air density (3% cooling loss per 1,000ft). Use hygrometers and HVAC integration for optimal 18-22°C, 40-50% RH environments.

Recent studies demonstrate that particulate concentration significantly impacts cooling systems. Environments with >50μg/m³ PM2.5 levels cause heatsink clogging 3x faster than clean rooms. Coastal areas face unique challenges due to salt aerosol deposition, which can reduce fan bearing lifespan by 40%. Implementing positive pressure configurations with HEPA-filtered intakes helps mitigate these issues. For high-altitude setups, consider 25% higher fan speeds or liquid cooling solutions to compensate for reduced air density.

| Altitude (ft) | Air Density (%) | Required Fan Speed Increase |

|---|---|---|

| 0 | 100% | 0% |

| 5,000 | 85% | 18% |

| 10,000 | 70% | 35% |

“Modern cooling requires holistic analysis – you can’t just throw fans at a problem. We’re seeing 30% efficiency gains from AI-driven predictive fan curves that anticipate thermal loads before they spike. Pair this with phase-change materials in next-gen heatsinks, and we’re redefining what ‘adequate cooling’ means.”

– Dr. Elena Voss, Thermal Architect at CryoDynamics

FAQ

- Q: Can case fans ever be too powerful?

- A: Yes – excessive static pressure causes turbulent airflow, reducing effective cooling by 18-25% (GN Labs). Match fan CFM to case volume.

- Q: Do RGB components affect temperatures?

- A: LED controllers add 2-5W heat load. Opt for passthrough PCBs in RGB strips to minimize thermal impact.

- Q: How dangerous is mineral oil submersion cooling?

- A: Requires specialized pumps and seals. Only 23% of DIY attempts succeed without leaks (Titan Rig study). Not recommended for beginners.