What is the difference between industrial PC and embedded PC?

admin3

- 0

Are you ready to dive into the world of industrial and embedded PCs? Whether you’re a tech enthusiast, a business owner looking for the right computing solution, or simply curious about cutting-edge technology, understanding the differences between these two types of computers is crucial. From robust industrial settings to compact embedded systems, each type offers unique features and capabilities that cater to specific needs. Let’s unravel the mysteries behind industrial and embedded PCs together!

Table of Contents

ToggleKey Features of an Industrial PC

Industrial PCs are designed to withstand harsh environments and demanding conditions within industrial settings. These robust computers are built with high-quality materials that can resist dust, dirt, moisture, vibrations, and extreme temperatures.

2024 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

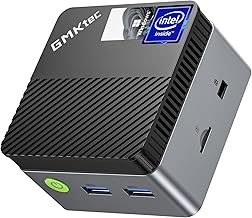

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

Key features of an industrial PC include a ruggedized casing for protection against physical damage, enhanced cooling systems to prevent overheating during continuous operation, and multiple expansion slots for flexibility in adding various peripherals.

Moreover, industrial PCs often come equipped with powerful processors, ample storage capacity, and long-term availability of components for extended product life cycles. They also offer compatibility with industry-specific software applications and protocols for seamless integration into existing systems.

In addition to their durability and reliability, industrial PCs provide extensive connectivity options such as Ethernet ports, USB interfaces, serial communication ports, and wireless connectivity capabilities. These features make them ideal for use in manufacturing plants, automation control systems…

Key Features of an Embedded PC

Embedded PCs are compact devices designed for specific tasks. They are built with customized hardware and software configurations to meet the requirements of a particular application. One key feature of an embedded PC is its small form factor, allowing it to fit into tight spaces or be integrated directly into machinery. Additionally, these PCs often have low power consumption, making them ideal for use in environments where energy efficiency is crucial.

Another important feature of embedded PCs is their reliability and durability. These devices are built to withstand harsh conditions such as extreme temperatures, vibrations, and humidity levels. This robust design ensures uninterrupted operation even in challenging industrial settings.

Furthermore, embedded PCs typically come with long product lifecycles and stable performance characteristics. This longevity makes them suitable for applications that require consistent functionality over an extended period without frequent upgrades or replacements.

In terms of connectivity, embedded PCs offer a variety of communication interfaces such as Ethernet ports, USB connections, serial ports, and wireless capabilities. This flexibility enables seamless integration with other equipment or systems for efficient data exchange and control processes.

The key features of an embedded PC make it a reliable solution for specialized applications that demand high performance in demanding environments while maintaining compact size and energy efficiency.

Use Cases for Industrial PCs

Industrial PCs are designed to withstand harsh environments, making them ideal for use in manufacturing plants, factories, and industrial settings where dust, moisture, and extreme temperatures are common. These rugged computers can handle demanding applications such as machine control, monitoring production lines, and managing inventory.

In the automotive industry, industrial PCs are used for quality control inspections on assembly lines. They ensure precision and accuracy in the manufacturing process. In the oil and gas sector, these robust computers monitor drilling operations and collect data in remote locations without fail.

Warehouses rely on industrial PCs for inventory management and logistics coordination. Their durability ensures uninterrupted performance even in challenging conditions. Industrial PCs play a crucial role in optimizing efficiency and productivity across various industries.

Use Cases for Embedded PCs

Embedded PCs are versatile tools that find applications in a wide range of industries. In the healthcare sector, they power medical devices and equipment, ensuring precise data processing and timely information delivery to healthcare professionals.

In the automotive industry, embedded PCs play a crucial role in vehicle systems, managing everything from engine diagnostics to entertainment systems seamlessly.

Within the retail sector, these compact computers are used for point-of-sale terminals and inventory management systems to enhance customer experience and operational efficiency.

Moreover, in industrial automation settings, embedded PCs control machinery and monitor processes with high reliability and stability.

Their small form factor makes them ideal for use in transportation applications like ticketing machines or onboard computer systems on trains or buses as well.

Performance Comparison between Industrial and Embedded PCs

When comparing the performance of industrial PCs and embedded PCs, several factors come into play. Industrial PCs are designed to handle demanding tasks in harsh environments with high processing power, making them suitable for applications requiring real-time data processing and control.

On the other hand, embedded PCs are optimized for specific functions within a device or system, offering efficient performance tailored to their designated roles. They excel in applications where space constraints and power efficiency are critical considerations.

Industrial PCs typically feature robust components such as powerful processors, high RAM capacity, and multiple connectivity options to support extensive operations seamlessly. Embedded systems prioritize compact designs, low power consumption, and customized configurations to meet specific application requirements efficiently.

Choosing between an industrial PC or an embedded PC depends on the intended use case and performance demands of the application at hand.

Price Comparison between Industrial and Embedded PCs

When it comes to comparing the prices of industrial PCs and embedded PCs, there are several factors that come into play. Industrial PCs tend to be more expensive due to their rugged design and higher processing power. These devices are built to withstand harsh industrial environments, making them durable but pricier.

On the other hand, embedded PCs are typically more cost-effective as they are designed for specific applications with lower processing requirements. Their compact size and efficiency make them a budget-friendly option for many projects.

It’s important to consider your specific needs and budget when deciding between an industrial PC and an embedded PC. While industrial PCs may have a higher upfront cost, they could save you money in the long run by reducing downtime and maintenance costs in demanding environments. Embedded PCs, on the other hand, offer affordability without compromising performance for less demanding applications.

Which one should you choose?

When deciding between an industrial PC and an embedded PC, it’s crucial to consider your specific needs. If you require a robust system capable of withstanding harsh environments and demanding tasks, an industrial PC might be the right choice for you. On the other hand, if space is limited and energy efficiency is a priority, an embedded PC could be more suitable.

Furthermore, think about the level of customization required for your application. Industrial PCs offer greater flexibility in terms of expandability and connectivity options, making them ideal for complex projects that demand scalability. Embedded PCs, on the other hand, are often more compact and optimized for specific functions.

The decision between an industrial PC and an embedded PC will depend on factors such as environmental conditions, performance requirements, budget constraints, and long-term goals. Be sure to evaluate these aspects carefully before making your choice.

Conclusion

Both industrial PCs and embedded PCs have their unique features and use cases. Industrial PCs are built for rugged environments and heavy-duty applications, while embedded PCs are designed for specific tasks with space-saving requirements.

When deciding between an industrial PC and an embedded PC, consider the environment in which it will be used, the necessary performance level, as well as budget constraints. The choice between the two types of computers will depend on your specific needs and requirements.