Why is PLC preferred over PC in factories?

admin3

- 0

Step into the world of manufacturing, where precision and efficiency reign supreme. In this dynamic environment, two technologies play a crucial role: Programmable Logic Controllers (PLC) and Personal Computers (PC). While both have their merits, PLC has emerged as the preferred choice in factories worldwide. Let’s delve deeper into why PLC is stealing the spotlight over PC on factory floors.

Table of Contents

ToggleAdvantages of PLC in factories

PLCs, or Programmable Logic Controllers, are the backbone of modern industrial automation. Their advantages in factories are undeniable. PLCs offer unparalleled reliability in controlling complex processes without human intervention. This reliability ensures consistent and accurate operation, reducing downtime and maximizing productivity.

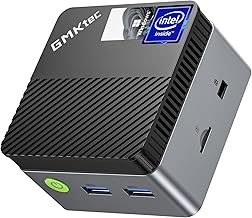

2024 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

Furthermore, PLCs provide flexibility to adapt to changing production requirements quickly and efficiently. With their programmable nature, adjustments to processes can be made on-the-fly without the need for extensive reprogramming or hardware changes.

Additionally, troubleshooting and maintenance of PLC systems are straightforward due to their modular design. Faulty components can be easily identified and replaced, minimizing disruption to operations.

The advantages of using PLCs in factories contribute significantly to increased efficiency, cost savings, and improved overall performance.

A. Reliability

When it comes to the reliability of PLC systems in factories, they truly shine. PLCs are specially designed to withstand harsh industrial environments, ensuring uninterrupted operation even in challenging conditions. These robust devices are built to last and have a proven track record of reliability, making them the preferred choice for critical processes in manufacturing plants.

Unlike PCs that may suffer from software or hardware issues leading to downtime, PLCs offer consistent performance without the risk of crashes. With their dedicated microprocessors and real-time operating systems, PLCs can execute tasks with precision and efficiency, minimizing the chances of system failures.

Moreover, PLCs come equipped with redundancy features such as backup power supplies and communication modules to enhance their reliability further. This redundant design ensures that even if one component fails, the system can continue functioning seamlessly without disruption.

B. Flexibility

PLCs offer unmatched flexibility in factory settings. With programmable logic controllers, manufacturers can easily modify and adapt processes without the need for extensive reprogramming or hardware changes. This agility allows for quick adjustments to production lines based on changing demands or new product requirements.

The versatility of PLCs enables seamless integration with various devices and systems, providing a cohesive control solution across different operations within a facility. Whether it’s regulating temperatures, managing conveyor belts, or monitoring inventory levels, PLCs excel at handling diverse tasks efficiently.

Moreover, the modular nature of PLC systems allows for scalability as businesses grow and evolve. Manufacturers can expand their automation capabilities by simply adding more modules to accommodate additional functions or increased production volumes.

The flexibility offered by PLC technology empowers factories to optimize processes, enhance productivity, and stay competitive in dynamic market environments.

C. Easy troubleshooting and maintenance

When it comes to troubleshooting and maintenance in factories, PLC systems have a clear edge over PCs. The structured programming language of PLC makes it easier for technicians to identify and resolve issues efficiently. With dedicated hardware designed for industrial environments, PLCs are built to withstand harsh conditions, reducing the risk of breakdowns.

Additionally, PLCs offer diagnostic tools that help pinpoint problems quickly without the need for extensive manual intervention. This not only saves time but also minimizes production downtime, ensuring smooth operations within the factory. In case of any faults or errors, technicians can easily access logs and historical data stored in the PLC system to track down issues promptly.

Easy troubleshooting and maintenance are key benefits that contribute to the reliability and efficiency of using PLCs in factories. By streamlining the process of identifying and fixing problems swiftly, PLC technology helps companies maintain high productivity levels while keeping operational costs low.

Limitations of PC in factories

While PCs are powerful devices, they come with limitations when used in factory settings. One major drawback is the high cost associated with setting up and maintaining a PC-based system in an industrial environment. From specialized hardware requirements to software licenses, the expenses can quickly add up, making it less cost-effective than PLCs.

Moreover, PCs are more vulnerable to viruses and crashes compared to PLCs. In factories where uninterrupted operation is crucial for production efficiency, any downtime caused by a virus attack or system crash can result in significant losses. The complex nature of PC systems also requires skilled IT professionals for troubleshooting and maintenance, adding another layer of complexity to factory operations.

While PCs have their place in certain applications within a factory setting, their limitations make PLCs the preferred choice for ensuring reliability and efficiency on the manufacturing floor.

A. High cost

When considering the use of PCs in factories, one significant drawback is the high cost associated with their implementation. Unlike PLCs which are designed specifically for industrial automation, PCs require additional hardware and software that can quickly escalate expenses. From purchasing powerful processors to installing specialized programs, the initial investment for using PCs in a factory setting can be substantial.

Moreover, ongoing maintenance costs can also add up over time. PC systems may require constant updates and upgrades to keep up with changing technology standards. This continuous need for investment can strain budgets and impact overall profitability for manufacturing facilities.

Additionally, the complexity of integrating various components within a PC system can lead to higher installation costs compared to PLCs. Factor in potential compatibility issues between different software and hardware components, and you have a recipe for increased expenses throughout the lifecycle of using PCs in factories.

In light of these financial considerations, many industries opt for PLCs due to their cost-effectiveness and tailored functionality specifically geared towards industrial applications.

B. Vulnerability to viruses and crashes

PCs, while powerful in their own right, can pose a significant risk when it comes to viruses and crashes in factory settings. The interconnected nature of PCs makes them susceptible to malware and cyber attacks, which can compromise critical operations within the manufacturing process.

Viruses have the potential to disrupt production schedules, damage equipment, and compromise sensitive data stored on PCs. Moreover, system crashes on PCs can lead to downtime and lost productivity for factories relying on these devices for automation and control purposes.

The need for constant updates and security measures to protect PCs from vulnerabilities adds an extra layer of complexity and cost for factory managers. Additionally, recovering from a virus attack or system crash can be time-consuming and resource-intensive, further impacting the efficiency of factory operations.

In contrast, PLCs offer a more secure and stable solution due to their dedicated hardware design that is less prone to external threats like viruses. This inherent resilience makes PLCs a preferred choice for ensuring uninterrupted production processes in industrial environments where reliability is paramount.

Case studies of successful implementation of PLC in factories

One notable case study showcasing the success of PLC implementation in factories comes from a large automotive manufacturing plant. By integrating PLC systems into their production lines, they were able to increase efficiency and reduce downtime significantly. This resulted in higher productivity levels and cost savings for the company.

Another interesting example is a food processing facility that adopted PLC technology to automate their packaging process. The precision and accuracy provided by PLCs not only improved product quality but also streamlined operations, leading to faster turnaround times and increased customer satisfaction.

Furthermore, a pharmaceutical company successfully utilized PLCs to monitor and control various stages of their drug manufacturing process. The real-time data obtained allowed for better quality control measures, ensuring compliance with regulatory standards while optimizing production output.

These case studies demonstrate the diverse applications of PLCs in different industries, highlighting their effectiveness in enhancing operational performance and driving business growth.

Future possibilities of PLC technology

The future of PLC technology in factories is filled with exciting possibilities. As advancements continue to be made in automation and connectivity, PLCs are expected to become even more integrated into the Industrial Internet of Things (IIoT) ecosystem. This integration will allow for seamless communication between various machines and systems within a factory environment.

Furthermore, the development of AI and machine learning algorithms will enable PLCs to optimize processes dynamically based on real-time data analysis. This means that factories can achieve higher levels of efficiency and productivity without human intervention.

Another exciting prospect is the potential for increased cybersecurity measures to be implemented within PLC systems. With the rise of cyber threats targeting industrial environments, enhancing security protocols will be crucial in safeguarding sensitive data and operations.

The future holds immense promise for PLC technology, paving the way for smarter, more interconnected, and secure manufacturing facilities.

Conclusion

PLCs have proven to be the backbone of modern manufacturing processes, offering unparalleled reliability, flexibility, and ease of maintenance. Their ability to operate seamlessly in industrial environments where PCs often struggle due to cost and vulnerability issues makes them the preferred choice for factories worldwide.

As technology continues to advance, PLCs are expected to evolve even further, incorporating more advanced features and capabilities. With their track record of success in various industries and their potential for future growth, it’s clear that PLCs will continue to play a crucial role in shaping the future of factory automation.

The preference for PLC over PC in factories is not just a trend but a strategic decision based on practicality and efficiency. By leveraging the strengths of PLC technology, manufacturers can streamline operations, increase productivity, and stay ahead in an increasingly competitive market landscape.