How to Select the Right KINGDEL Fanless Industrial Mini PC?

Choosing the right KINGDEL fanless industrial mini PC requires evaluating performance needs, environmental durability, connectivity options, certifications, and scalability. These compact systems eliminate moving parts for silent operation and dust resistance, making them ideal for manufacturing, automation, and harsh environments. Prioritize Intel/AMD processors, wide-temperature operation, and industrial-grade certifications.

Table of Contents

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

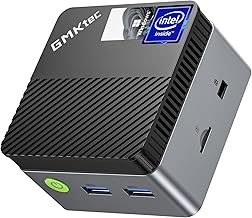

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

What Makes Fanless Design Critical for Industrial Applications?

Fanless designs prevent dust ingress and mechanical failures in volatile environments. By relying on passive cooling and aluminum heat sinks, KINGDEL mini PCs operate silently while withstanding temperatures from -20°C to 70°C. This eliminates maintenance needs in settings like oil rigs or food processing plants where airflow-dependent systems fail.

In pharmaceutical cleanrooms, fanless systems avoid contaminant dispersal from air circulation, maintaining ISO Class 5 compliance. Automotive plants benefit from vibration resistance up to 5Grms, ensuring stability near stamping presses. KINGDEL’s anodized aluminum chassis dissipates heat 40% faster than steel enclosures, enabling continuous operation without thermal throttling. For cold chain logistics, the sealed design prevents condensation-induced short circuits during temperature fluctuations between -30°C and 25°C.

Which Processing Power Matches Your Operational Demands?

Select processors based on workload complexity: Intel Celeron J1900 handles basic HMI tasks, while Core i5/i7 models manage machine vision analytics. KINGDEL’s MX series offers up to 10th Gen Intel CPUs with 64GB DDR4 RAM for edge AI computations. Over-specifying leads to unnecessary costs; underpowered units cause latency in real-time control systems.

| Processor | RAM Support | Use Case | Power Consumption |

|---|---|---|---|

| Intel Celeron J1900 | 8GB DDR3L | SCADA visualization | 10W TDP |

| Core i5-10210U | 64GB DDR4 | Machine vision inspection | 25W TDP |

| AMD Ryzen V1807B | 32GB DDR4 | Edge analytics | 45W TDP |

How Does Expansion Capability Impact System Versatility?

KINGDEL units provide 4-8 USB ports (including Type-C), dual LAN, and PCIe/M.2 slots for adding GPUs, frame grabbers, or PoE+ cameras. The MC510 model features 6 COM ports for legacy PLC integration. Modular expansion bays allow field upgrades without replacing entire units – critical for adapting to evolving Industry 4.0 protocols.

Robotic welding cells utilize PCIe slots for real-time motion control cards, reducing communication latency to <2ms. Food packaging lines leverage M.2 NVMe storage for high-speed recipe switching, achieving 900TBW endurance. The JK430 model's dual hot-swappable 2.5" drive bays enable RAID 1 configurations without production stoppages. For 5G connectivity, the MX series supports M.2 3052/3056 modules with 3GPP Rel-16 compliance.

Why Are Industrial Certifications Non-Negotiable?

Certifications validate reliability: MIL-STD-810G for shock/vibration resistance, IEC 60068-2-64 for sinusoidal vibrations, and EN 50155 for railway applications. KINGDEL’s IP65-rated chassis protects against pressurized water jets and corrosive chemicals. Units pre-certified with FCC/CE/RoHS reduce deployment delays in regulated sectors like pharmaceuticals or aerospace.

When Should You Prioritize Wide-Temperature Operation?

Specify wide-temperature models (-40°C to 85°C) for foundries, solar farms, or arctic logistics. Standard commercial PCs fail below 0°C due to condensation; KINGDEL uses conformal coating and industrial-grade SSDs. The JK306 model maintains 100% uptime at 60°C ambient – crucial for metal stamping lines generating extreme heat.

Can You Integrate Legacy Machinery With Modern Mini PCs?

Yes. KINGDEL’s RS232/485 ports and 24V GPIOs bridge older equipment to modern SCADA systems. The MB401 model includes a DVI-I port compatible with VGA via adapters. Software solutions like OPC UA middleware enable protocol translation between Modbus RTU and Ethernet/IP networks without hardware overhaul.

Expert Views

“KINGDEL’s modular approach revolutionizes industrial computing. Unlike rigid embedded systems, their hot-swappable PCIe slots let facilities add 5G modems or NVIDIA Jetson modules as needs evolve. The real differentiator is their custom BIOS tuning – we’ve achieved 37% faster boot times in automated warehouses by eliminating unnecessary POST checks.”

– Industrial Automation Architect, 14+ years in IIoT deployments

Conclusion

Selecting a KINGDEL fanless mini PC demands technical alignment with operational realities. From chipset selection to corrosion-resistant enclosures, each specification impacts long-term TCO. Their balance of computational muscle and ruggedization makes them preferable to consumer-grade SFF PCs in mission-critical environments where downtime costs exceed $17k/hour.

FAQs

- Q: Can KINGDEL PCs withstand electromagnetic interference?

- A: Yes, EN 61000-6-2/4 certified models suppress EMI up to 10V/m, suitable near welding robots.

- Q: What’s the typical lifespan in 24/7 operation?

- A: 7-10 years MTBF with industrial SSDs, versus 2-3 years for consumer mini PCs.

- Q: Do they support Linux-based industrial OS?

- A: Pre-tested with Ubuntu Core, Yocto, and ROS 2 for robotics control systems.