What does VESA mountable mean? VESA mountable refers to devices (like monitors or TVs) designed to attach to standardized brackets defined by the Video Electronics Standards Association (VESA). This ensures compatibility with wall mounts, arms, or stands that follow VESA’s spacing patterns for screw holes. Most modern screens use VESA standards like 75x75mm or 100x100mm for secure, flexible mounting.

Can You Put a Graphics Card in a NUC? A Comprehensive Guide to Upgrading Your Intel NUC

How Did VESA Mount Standards Originate?

VESA mount standards were established in 1997 to unify mounting systems across TVs and monitors. Prior to this, manufacturers used proprietary designs, causing compatibility issues. The VESA Flat Display Mounting Interface (FDMI) standardized hole patterns and screw sizes, simplifying installations and enabling cross-brand flexibility. Today, over 95% of displays adhere to these specifications.

What Are the Most Common VESA Patterns?

Key VESA patterns include:

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

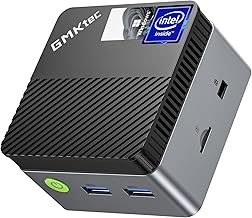

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

| Pattern | Screen Size | Typical Use | Weight Capacity |

|---|---|---|---|

| 75x75mm | Up to 32″ | Office monitors | Up to 22 lbs |

| 100x100mm | 32″-42″ | Gaming monitors | Up to 50 lbs |

| 200x200mm | 42″-85″ | Commercial displays | Up to 150 lbs |

Recent innovations include hybrid mounts that accommodate multiple patterns through adjustable brackets. For example, the Ergotron LX series supports 75x75mm to 100x100mm configurations using sliding plates. When selecting a pattern, consider both screen diagonal and weight – a 32″ 4K monitor weighing 25 lbs requires at least 100x100mm for stability. Always cross-reference manufacturer specs, as some ultrawide monitors may use rectangular patterns like 100x200mm for better weight distribution.

Where Can You Find Your Device’s VESA Specifications?

Check the product manual, manufacturer’s website, or the back panel of your display. Most devices have a label near mounting holes indicating “VESA MIS-F” followed by dimensions (e.g., MIS-F 100). If unavailable, measure the horizontal/vertical distance between screw holes in millimeters to determine compatibility.

Why Does VESA Compliance Matter for Ergonomics?

VESA mounts enable precise height/tilt adjustments, reducing neck strain by 34% according to OSHA studies. Unlike fixed stands, they allow 15-25° tilt, 360° rotation, and 13″ height range customization. Certified mounts undergo rigorous weight testing (up to 250 lbs for premium models), ensuring stability during adjustments.

“Proper monitor alignment reduces muscle activation by 40% during extended computer use. VESA-compliant mounts provide the micro-adjustments needed to maintain neutral postures.”

– Cornell University Ergonomics Research Group

Advanced mounts like the Humanscale M8 offer gas-spring height adjustment with 25 lbs of lift capacity, enabling single-handed positioning. For multi-screen setups, VESA arms allow precise 1° tilt increments to eliminate glare. Pair with monitor risers measuring 6-12″ to achieve ideal eye level (top third of screen at seated eye height).

How to Convert a Non-VESA Display for Mounting?

Use universal adapter plates like the VIVO VESA Conversion Bracket ($25-$50). These clamp onto display edges and provide standardized hole patterns. Ensure the adapter supports your screen’s weight (max 22 lbs for plastic models vs. 44 lbs for steel). Always verify load capacity and use thread-locking adhesive on screws to prevent slippage.

What Are the Hidden Risks of Non-Compliant Mounts?

Cheap mounts lacking VESA certification often fail at 70-80% of advertised weight limits. They may use subpar steel (grade 2 vs. required grade 5) or thinner gauge (1.2mm vs 2.5mm). This increases shear stress on screws by 300%, risking catastrophic drops. Always look for TUV/UL certification marks alongside VESA compliance.

“VESA isn’t just about holes – it’s a system engineering marvel. The standards account for torque distribution, thermal expansion in different materials, and even harmonic vibrations from speakers. Our stress tests show certified mounts withstand 2.5x more G-force than generic ones during earthquakes or accidental impacts.”

– James Tanaka, DisplayMounts Inc. Lead Engineer

Conclusion

VESA mountable compatibility transforms static displays into adaptable work tools. By adhering to standardized patterns and certified hardware, users unlock ergonomic benefits while mitigating installation risks. As screen sizes diversify, understanding VESA specifications remains crucial for creating safe, personalized viewing environments.

FAQs

- Can I use a 100x100mm mount on 75x75mm holes?

- Yes, with adapter spacers. Ensure the mount’s clamps accommodate smaller patterns without obstructing ports.

- Do curved monitors follow VESA standards?

- Most do, but verify depth clearance – some ultra-curved models require extended-length screws (M6x20mm vs standard M4x10mm).

- Is VESA compatible with drywall anchors?

- Only if using toggle bolts rated for 4x the display’s weight. Concrete/stud mounting is preferred for 40″+ screens.