An Industrial PC (IPC) is a robust computer specifically designed for industrial applications, capable of operating reliably in harsh environments. Unlike consumer-grade computers, IPCs are built to withstand extreme temperatures, vibrations, dust, and moisture, making them essential for automation and control in various industries.

What Is an Industrial PC (IPC)?

An Industrial PC (IPC) is a specialized computer designed for use in industrial environments. These systems are engineered to handle demanding tasks such as process control, data acquisition, and automation. They typically feature enhanced durability, allowing them to function effectively in conditions that would be detrimental to standard consumer computers.Chart: Overview of IPC Characteristics

2024 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

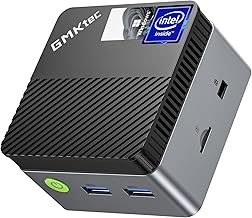

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

| Characteristic | Description |

|---|---|

| Durability | Built to withstand harsh industrial conditions |

| Customization | Can be tailored for specific applications |

| Longevity | Designed for long-term operation |

| Performance | High processing power for demanding tasks |

How Do IPCs Differ From Consumer-Grade Computers?

IPCs differ significantly from consumer-grade computers in several ways:

- Durability: IPCs are constructed with rugged components that resist environmental hazards like dust and moisture.

- Performance: They often use higher-performance processors suitable for continuous operation under load.

- Customization: IPCs can be configured with specific I/O interfaces and software tailored to industrial needs.

- Reliability: With a higher mean time between failures (MTBF), IPCs are designed for 24/7 operation.

What Are the Key Features of Industrial PCs?

Key features of Industrial PCs include:

- Robust Construction: Designed to endure extreme temperatures, humidity, and vibrations.

- Versatile Connectivity: Equipped with various I/O ports such as USB, Ethernet, and serial ports for connecting to sensors and other devices.

- Modular Design: Many IPCs have modular components that allow for easy upgrades and maintenance.

- Real-Time Processing: Capable of running real-time operating systems (RTOS) for critical applications.

Chart: Key Features of IPCs

| Feature | Description |

|---|---|

| Robust Construction | Can withstand harsh conditions |

| Versatile Connectivity | Multiple I/O options for device integration |

| Modular Design | Easy upgrades and maintenance |

| Real-Time Processing | Suitable for critical applications |

In What Environments Are Industrial PCs Typically Used?

Industrial PCs are commonly used in various environments, including:

- Manufacturing Plants: For controlling machinery and monitoring production lines.

- Transportation Systems: In logistics for tracking shipments and managing inventory.

- Energy Sector: For monitoring equipment in power plants and renewable energy facilities.

- Food Processing: To ensure compliance with hygiene standards while managing production processes.

What Industries Benefit From Using IPCs?

Numerous industries benefit from the implementation of IPCs:

- Manufacturing: Enhances automation processes and improves efficiency.

- Automotive: Used for design simulations, quality control, and assembly line management.

- Pharmaceutical: Ensures precise monitoring of production processes while adhering to regulatory standards.

- Telecommunications: Manages network operations and infrastructure monitoring.

How Do IPCs Enhance Automation and Control Processes?

IPCs play a crucial role in enhancing automation by:

- Data Processing: Allowing real-time data analysis from sensors and machinery.

- Control Systems Integration: Facilitating seamless communication between different components in an automated system.

- User Interfaces: Providing operators with visual feedback through HMIs (Human-Machine Interfaces) for easier management.

What Are the Advantages of Using IPCs in Industrial Settings?

The advantages of using IPCs include:

- Increased Efficiency: Streamlined operations lead to reduced downtime and improved productivity.

- Cost Savings: Long-term reliability reduces maintenance costs compared to consumer-grade systems.

- Scalability: Easily integrated into existing systems while allowing future expansions.

How Do IPCs Support Data Acquisition and Process Visualization?

IPCs support data acquisition by collecting data from various sensors and devices throughout an industrial environment. This data can then be visualized through user-friendly interfaces, enabling operators to monitor processes effectively, identify issues quickly, and make informed decisions based on real-time information.Chart: Data Acquisition Process

| Step | Description |

|---|---|

| Data Collection | Gathering data from sensors |

| Data Processing | Analyzing data in real-time |

| Visualization | Displaying data through dashboards or HMIs |

What Are the Common Specifications of Industrial PCs?

Common specifications include:

- Processor Types: Often equipped with Intel or AMD processors designed for high performance.

- Memory Options: Typically range from 4GB to 64GB or more depending on application needs.

- Storage Solutions: SSD or HDD options providing varying capacities suited for different applications.

How Does the Design of IPCs Cater to Harsh Environments?

The design features that cater to harsh environments include:

- Sealed Enclosures: Protect against dust, moisture, and contaminants.

- Shock Resistance: Built to withstand vibrations typical in industrial settings.

- Temperature Tolerance: Operate effectively across a wide range of temperatures.

Industrial News

The industrial PC market is experiencing significant growth due to increasing demand for automation across various sectors such as manufacturing, energy, and transportation. Recent advancements focus on enhancing connectivity features, integrating IoT capabilities, and improving ruggedness to meet the challenges posed by modern industrial environments. Manufacturers are also emphasizing energy efficiency as part of their product offerings.

Expert Views

“Industrial PCs are transforming how industries operate by providing robust solutions that withstand harsh conditions while delivering high performance,” says tech analyst Dr. Sarah Thompson. “As industries move towards greater automation and connectivity, the role of IPCs will only become more critical in ensuring efficient operations.”