A PLC (Programmable Logic Controller) is a ruggedized computer designed for industrial automation, specializing in real-time control of machinery via ladder logic. An Industrial PC (IPC) is a hardened computer running standard operating systems, capable of complex tasks like data analysis and HMI management. While PLCs excel in reliability for repetitive tasks, IPCs offer flexibility and scalability for advanced applications.

Can Mini PCs Handle Video Editing and Graphic Design? A Comprehensive Review

How Do PLCs and Industrial PCs Function in Automation Systems?

PLCs execute deterministic control tasks, such as managing conveyor belts or sensors, using ladder logic or structured text. Industrial PCs handle multitasking operations, combining control functions with data logging, visualization, and communication with enterprise systems. PLCs prioritize low-latency responses, while IPCs integrate IT and OT layers for smart factory environments.

In modern production lines, PLCs typically manage device-level communication through fieldbus protocols like PROFINET or EtherCAT, ensuring synchronized operation of motors and actuators. IPCs often sit higher in the control hierarchy, aggregating data from multiple PLCs to perform system-wide analytics. For example, an IPC might analyze vibration data from 50 PLC-controlled pumps to predict bearing failures, while each PLC maintains precise RPM control of its assigned pump. This layered approach allows PLCs to maintain millisecond-level response times while IPCs handle computationally intensive tasks without compromising real-time operations.

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

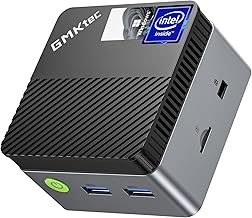

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

What Are the Key Hardware Differences Between PLCs and IPCs?

PLCs use modular, task-specific I/O modules and lack general-purpose computing components. Industrial PCs feature x86 processors, SSDs, and expansion slots for GPUs or additional RAM. PLCs operate in extreme temperatures (-20°C to 60°C) with passive cooling, while IPCs require active cooling but support higher computational workloads like machine vision.

| Feature | PLC | IPC |

|---|---|---|

| Processor | ARM/RISC-based | x86/x64 |

| Memory | 2-8 MB SRAM | 8-64 GB DDR4 |

| I/O Channels | Up to 512 dedicated | Via expansion cards |

What Are the Cybersecurity Implications for PLCs vs. IPCs?

PLCs face risks like ladder logic injection attacks but lack attack surfaces like USB ports. IPCs, running Windows/Linux, require patch management and firewall rules. The 2021 Colonial Pipeline hack exploited an IPC’s VPN vulnerability, highlighting the need for IEC 62443 compliance in converged systems.

PLCs traditionally relied on “security through obscurity” with proprietary firmware, but modern Ethernet-enabled PLCs now require secure boot mechanisms and role-based access control. IPCs demand regular OS updates and application whitelisting – a challenge in 24/7 manufacturing environments. Recent NIST guidelines recommend network segmentation strategies where PLCs operate in isolated VLANs while IPCs use encrypted tunnels for cloud communication. Both devices now support TPM 2.0 modules for secure key storage, though implementation varies between vendors.

“The PLC vs. IPC debate hinges on lifecycle costs. While PLCs have 10+ year lifespans, IPCs offer future-proofing via GPU acceleration for digital twins. However, OT engineers often underestimate the maintenance overhead of IPC cybersecurity hardening.” – Industrial Automation Architect, Siemens Certified Partner

FAQ

- Can an Industrial PC replace a PLC entirely?

- Not in safety-rated applications (SIL 3/PL e), but IPCs can supplement PLCs in supervisory roles.

- Do IPCs support legacy fieldbus protocols?

- Yes, via expansion cards (Profibus, DeviceNet), but latency may increase vs. native PLC interfaces.

- Which has lower TCO (Total Cost of Ownership)?

- PLCs cost less long-term in stable environments; IPCs provide ROI in data-driven optimization scenarios.