How do Industrial PCs and Embedded PCs differ in design and application?

Industrial PCs (IPCs) are rugged computers designed for harsh environments, emphasizing durability and scalability. Embedded PCs are compact, task-specific systems integrated into larger machinery. IPCs handle complex industrial automation, while Embedded PCs focus on dedicated functions like control systems. Key differences include environmental tolerance, customization, and use cases.

Can Mini PCs Handle Video Editing and Graphic Design? A Comprehensive Review

Table of Contents

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

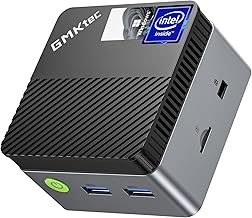

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

How Do Industrial PCs and Embedded PCs Differ in Core Design?

Industrial PCs prioritize ruggedness, with fanless cooling, shock-resistant casings, and extended temperature ranges (-40°C to 85°C). They support modular expansions like PCIe slots for specialized I/O cards. Embedded PCs use soldered components (e.g., eMMC storage) for compactness, sacrificing upgradability. Example: AVEVA’s IPC withstands factory vibrations, while Raspberry Pi Compute Module 4 serves as an embedded solution for IoT gateways.

Industrial PCs often employ modular motherboards with replaceable CPU modules, enabling technology upgrades without full system replacement. For instance, Beckhoff’s CX20xx series allows swapping Intel Core processors while retaining the same chassis. Embedded systems typically use system-on-chip (SoC) designs where CPU, GPU, and memory share a single substrate. This integration improves energy efficiency but limits hardware refresh options. Thermal management differs significantly – IPCs use aluminum heat sinks with convection cooling, while embedded PCs rely on passive cooling through PCB layout optimization.

What Are the Key Environmental Tolerance Variations?

IPCs meet IP67 ratings for dust/water resistance and MIL-STD-810G for shock/vibration. Embedded PCs typically adhere to IP30-IP54, focusing on minimal particulate ingress. Phoenix Contact’s RFC 470S IPC operates in -25°C to 60°C with 95% humidity, whereas Kontron’s embedded boards tolerate -40°C to 85°C but lack full-sealed enclosures, making them unsuitable for washdown zones.

Which Industries Favor Industrial PCs Over Embedded Systems?

Manufacturing, oil/gas, and pharmaceuticals use IPCs for SCADA and MES due to real-time processing needs. Automotive plants deploy IPCs for robotic control (e.g., Beckhoff CX20xx). Embedded PCs dominate consumer electronics, smart appliances, and retail POS systems. ABB’s AC500 PLC uses embedded cores, while Siemens SIMATIC IPC3000 manages assembly line analytics.

How Do Power Requirements Contrast Between the Two Systems?

IPCs use 24V DC or 100-240V AC with 50W-300W consumption, supporting high-performance CPUs like Intel Xeon. Embedded PCs run on 5V-12V DC with 5W-15W draw, utilizing ARM/RISC-V processors. Advantech’s UNO-2484G IPC consumes 240W for edge AI, while NVIDIA Jetson Nano (embedded) uses 10W for machine vision tasks.

| Feature | Industrial PC | Embedded PC |

|---|---|---|

| Power Source | 24V DC/100-240V AC | 5V-12V DC |

| Typical Consumption | 50W-300W | 5W-15W |

| Common Processors | Intel Xeon, Core i7 | ARM Cortex, RISC-V |

What Are the Maintenance and Lifespan Differences?

IPCs offer hot-swappable drives and 5-10 year lifecycle guarantees (e.g., Dell OptiPlex 3000 IPC). Embedded PCs have non-replaceable components with 3-5 year lifespans. WinSystems’ EPX-APL2 IPC allows RAM/SSD swaps, whereas Raspberry Pi’s embedded modules require full replacement upon failure, increasing long-term TCO in industrial settings.

Industrial PCs often feature redundant power supplies and ECC memory to minimize downtime in critical operations. Maintenance cycles differ substantially – IPCs undergo scheduled component inspections (fans, capacitors) every 6-12 months, while embedded systems are typically maintained through firmware updates rather than hardware interventions. The mean time between failures (MTBF) for IPCs averages 100,000 hours compared to 30,000 hours for embedded systems. However, embedded solutions benefit from simpler architecture with fewer failure points in controlled environments.

Can Embedded PCs Handle Real-Time Operating Systems (RTOS)?

Yes, embedded PCs often run RTOS like VxWorks or FreeRTOS for deterministic responses. However, IPCs support heavier RTOS variants (e.g., QNX Neutrino) with multi-core processing. Example: Wind River’s VxWorks powers Mars rovers’ embedded systems, while Rockwell Automation’s IPCs use QNX for sub-millisecond PLC cycle times.

How Does Cybersecurity Implementation Vary?

IPCs integrate TPM 2.0 chips and support Windows IoT Enterprise LTSC for patching. Embedded PCs rely on secure boot and minimal OS footprints (Yocto Linux) to reduce attack surfaces. Moxa’s TN-5510 IPC includes hardware firewalls, whereas embedded solutions like Toradex Colibri use encrypted U-Boot for firmware validation.

“The convergence of IPCs and embedded PCs is accelerating with edge computing. While IPCs dominate heavy industry, ARM-based embedded systems now rival x86 in processing – see NXP’s i.MX 8M Plus with 2.3 TOPS AI acceleration. Future differentiation will hinge on software ecosystems rather than hardware specs.” – Industrial Automation Architect, 15+ years in IIoT deployments

Conclusion

Industrial PCs excel in harsh, scalable environments with modularity, while Embedded PCs prioritize cost and space efficiency for fixed functions. Selection depends on operational lifespan, environmental stressors, and computational demands. Hybrid solutions like Advantech’s EPC-APL are blurring traditional boundaries, offering configurable embedded modules within IPC-grade chassis.

FAQs

- Can an Embedded PC Replace an Industrial PC?

- Only in mild environments with fixed tasks. Embedded PCs lack the expandability and wide-temperature components needed for most Industry 4.0 applications. Exceptions include CODESYS-controlled machines using Raspberry Pi CM4 with DIN-rail enclosures.

- Which Offers Better ROI: IPC or Embedded PC?

- IPCs have higher upfront costs ($2k-$15k) but lower TCO over 7+ years. Embedded PCs ($200-$1.5k) suit short-lifecycle projects. A 2023 ABB study found IPCs reduce downtime costs by 62% versus embedded in automotive plants.

- Do Embedded PCs Support Machine Learning?

- Yes, via TensorFlow Lite or OpenVINO on platforms like Intel’s Elkhart Lake embedded CPUs. However, IPCs with NVIDIA RTX A2000 GPUs handle larger models (ResNet-50) at 3x inference speeds.