A Programmable Logic Controller (PLC) and an Industrial PC (IPC) serve distinct roles in industrial automation. While both are used for control and monitoring, PLCs are designed specifically for real-time control tasks, whereas IPCs offer broader computing capabilities suitable for complex data processing. Understanding their differences is essential for selecting the right technology for specific applications.

What Is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is a specialized digital computer used for automation of industrial processes. It is designed to perform real-time control tasks, such as monitoring inputs from sensors, executing logic operations, and controlling outputs to machinery. PLCs are built to be reliable in harsh environments, making them ideal for manufacturing, assembly lines, and process control.Chart: Key Features of PLCs

2024 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

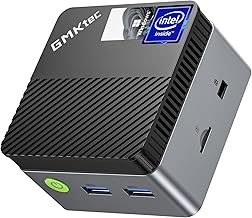

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

| Feature | Description |

|---|---|

| Real-Time Operation | Executes control tasks immediately based on inputs |

| Rugged Design | Built to withstand extreme conditions |

| Modular Architecture | Allows easy expansion with additional I/O modules |

| Programming Language | Typically uses ladder logic or function block diagrams |

What Is an Industrial PC (IPC)?

An Industrial PC (IPC) is a robust computer designed for industrial applications that require high performance and reliability. Unlike standard personal computers, IPCs can operate under extreme conditions such as high temperatures, dust, and moisture. They can run various operating systems like Windows or Linux and support a wide range of applications including data processing, visualization, and control.Chart: Key Features of IPCs

| Feature | Description |

|---|---|

| Versatile Applications | Can run multiple software applications |

| High Processing Power | Suitable for complex calculations |

| Customizable | Can be tailored to specific industrial needs |

| Connectivity Options | Supports various I/O interfaces |

How Do PLCs and IPCs Differ in Functionality?

The primary difference between PLCs and IPCs lies in their functionality:

- Purpose: PLCs are specifically designed for real-time control of machinery, while IPCs can handle a broader range of tasks including data analysis.

- Operating Systems: PLCs typically use proprietary operating systems optimized for control tasks; IPCs can run general-purpose operating systems.

- Programming: Programming a PLC often involves specialized languages like ladder logic, whereas IPC programming can use high-level languages such as C++ or Python.

What Are the Typical Applications for PLCs and IPCs?

PLCs are commonly used in:

- Manufacturing Automation: Controlling assembly lines and robotic systems.

- Process Control: Managing operations in chemical plants or oil refineries.

- Building Automation: Regulating HVAC systems and lighting controls.

IPCs find applications in:

- Data Acquisition: Collecting data from various sensors for analysis.

- Visualization: Displaying real-time process data through graphical user interfaces.

- Complex Control Systems: Integrating multiple control functions into one system.

What Are the Key Specifications of PLCs?

Key specifications of PLCs include:

- Input/Output Capacity: The number of inputs/outputs it can handle simultaneously.

- Processing Speed: Measured in scan time; faster scan times allow quicker response to input changes.

- Memory Size: Determines how much program data can be stored.

What Are the Key Specifications of Industrial PCs?

Key specifications of IPCs include:

- Processor Type: Often equipped with powerful multi-core processors.

- RAM Size: Typically ranges from 4GB to 64GB or more depending on application needs.

- Storage Options: Can include SSD or HDD with varying capacities.

How Does Programming Differ Between PLCs and IPCs?

Programming methods differ significantly:

- PLCs use ladder logic or function block diagrams designed specifically for automation tasks, which may require specialized training.

- IPCs, on the other hand, can be programmed using widely-known programming languages like C++, Java, or Python, making them more accessible to a broader range of developers.

What Environmental Conditions Do PLCs and IPCs Withstand?

PLCs are built to endure harsh environments including:

- Temperature Extremes: Operate effectively in both high heat and low temperatures.

- Vibration Resistance: Designed to function without failure even in high-vibration settings.

- Moisture Protection: Often rated with IP67 or similar standards to resist dust and water ingress.

IPCs also withstand similar conditions but may vary based on specific models; many are designed with rugged enclosures to protect against environmental hazards.

In Which Industries Are PLCs Commonly Used?

PLCs are widely utilized across various industries including:

- Manufacturing: For controlling production lines.

- Oil & Gas: Monitoring drilling operations and safety systems.

- Food Processing: Ensuring compliance with hygiene standards while managing production processes.

In Which Industries Are Industrial PCs Commonly Used?

Industrial PCs find applications in:

- Utilities Management: Monitoring infrastructure such as water treatment plants.

- Transportation Systems: Managing logistics operations including tracking shipments.

- Automotive Manufacturing: Controlling assembly processes and quality assurance systems.

Industrial News

The industrial automation sector is witnessing significant advancements with the integration of both PLCs and industrial PCs into modern manufacturing processes. Recent trends indicate a growing preference for flexible solutions that combine the reliability of PLC technology with the computational power of industrial PCs. As industries continue to embrace Industry 4.0 principles, these technologies play crucial roles in enhancing efficiency, data analysis capabilities, and overall operational effectiveness.

Expert Views

“Understanding the differences between PLCs and industrial PCs is essential for businesses looking to optimize their automation processes,” says automation expert Dr. Michael Adams. “While both technologies have their strengths, selecting the right one depends on specific application needs—whether it’s real-time control or complex data processing.”