Short Answer: Mini-ITX motherboards cost more due to compact engineering challenges, specialized components, and lower production scales. Their design requires advanced thermal solutions, premium VRMs, and space-efficient layouts, which increase manufacturing costs. Limited market demand further drives prices higher compared to mass-produced ATX boards.

How Does Compact Design Influence Manufacturing Complexity?

Mini-ITX boards condense full-sized functionality into a 170x170mm footprint. This requires multi-layer PCBs (6-8 layers vs. 4-6 for ATX) and precision placement of components like PCIe slots and SATA ports. Engineers must mitigate signal interference in tight spaces, often using expensive materials like high-grade fiberglass or ceramic capacitors for stability.

The spatial constraints demand innovative trace routing techniques. For instance, the Gigabyte Z690I Aorus Ultra employs angled M.2 slots and stacked connectors to conserve space. Designers also face challenges with component spacing – capacitors and chokes must be positioned to avoid electromagnetic interference while staying within thermal limits. These engineering solutions require specialized software tools and extended prototyping phases, adding 20-30% to development timelines compared to ATX designs.

2025 Best 5 Mini PCs Under $500

| Best Mini PCs Under $500 | Description | Amazon URL |

|---|---|---|

|

Beelink S12 Pro Mini PC  |

Intel 12th Gen Alder Lake-N100, 16GB RAM, 500GB SSD, supports 4K dual display. | View on Amazon |

|

ACEMAGICIAN Mini Gaming PC  |

AMD Ryzen 7 5800U, 16GB RAM, 512GB SSD, supports 4K triple display. | View on Amazon |

|

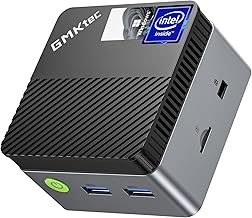

GMKtec Mini PC M5 Plus  |

AMD Ryzen 7 5825U, 32GB RAM, 1TB SSD, features WiFi 6E and dual LAN. | View on Amazon |

|

Maxtang ALN50 Mini PC ![Maxtang Ryzen 7 7735HS Mini PC [8C/16T up to 4.75GHz] Windows 11 Home Supported 32GB DDR5 Ram 1TB PCIe4.0 Nvme SSD WIFI6 BT5.2 Mini Desktop Gaming Computer](https://m.media-amazon.com/images/I/51oZECsOffL._AC_SX466_.jpg) |

Intel Core i3-N305, up to 32GB RAM, compact design with multiple connectivity options. | View on Amazon |

|

MINISFORUM Venus UM773 Lite  |

Ryzen 7 7735HS, up to 32GB RAM, supports dual displays and has solid performance. | View on Amazon |

| Design Aspect | Mini-ITX | ATX |

|---|---|---|

| PCB Layers | 6-8 | 4-6 |

| Trace Density | 140/cm² | 90/cm² |

| Component Clearance | 0.8mm | 1.5mm |

What Role Do Specialized Components Play in Cost?

Key components like robust VRMs (Voltage Regulator Modules) and advanced thermal solutions are mandatory for Mini-ITX. For example, the ASUS ROG Strix X570-I uses a 10+2 phase VRM with 60A power stages to handle overclocked CPUs—features typically reserved for high-end ATX boards. These parts cost 20-30% more than standard equivalents.

Manufacturers often use proprietary cooling solutions to manage heat in confined spaces. The MSI MEG Z690I Unify’s dual-chamber heatsink combines vapor-chamber technology with nano-carbon coating, a $15 premium over conventional aluminum heatsinks. Such components require custom manufacturing processes – the CNC-milled copper heatspreader on NZXT’s N7 Z690 adds $22 to production costs but is essential for maintaining sub-80°C VRM temperatures during sustained loads.

Why Are Production Volumes Lower for Mini-ITX Boards?

Only 5-7% of DIY PC builders opt for Mini-ITX, per Steam Hardware Survey data. Manufacturers produce smaller batches, losing economies of scale. A single production run for a model like the Gigabyte Z690I Aorus Ultra might yield 10,000 units vs. 100,000+ for ATX variants, spreading R&D and tooling costs across fewer units.

How Do Thermal Constraints Impact Engineering Costs?

Cooling a Mini-ITX board demands innovation. The MSI MEG Z690I Unify employs a 7W/mK thermal pad and dual-heatpipe design to dissipate 150W+ loads. Such solutions require custom molds and CFD simulations, adding $8-12 per unit. In contrast, ATX boards use simpler heatsinks costing $2-4.

What Market Dynamics Keep Prices Elevated?

The Mini-ITX market thrives on enthusiasts willing to pay premiums. Boards like the ASRock X670E PG-ITX/TB4 target niche users needing Thunderbolt 4 and PCIe 5.0—features absent in 85% of ATX boards. Limited competition (only 6 major brands offer Mini-ITX) allows sustained price points 40-60% above comparable ATX models.

“Mini-ITX isn’t just shrinking components—it’s reimagining power delivery and thermal physics. We’ve seen 15% annual R&D cost increases since 2020 to support PCIe 5.0 and DDR5 in these tiny boards. The $300+ price tier is the new normal for performance-grade ITX.”

– Michael Chen, Senior Engineer at GIGABYTE’s SFF Division

Conclusion

Mini-ITX motherboards command premium pricing due to their intricate engineering, specialized parts, and niche-market economics. While costs are unlikely to drop significantly, advancements in semiconductor miniaturization may narrow the gap with ATX boards by 2025.

FAQs

- Q: Can I use a Mini-ITX motherboard for gaming?

- A: Yes—boards like the ASUS ROG Crosshair X670E Extreme support RTX 4090 GPUs and Ryzen 9 7950X CPUs, but expect 5-10% higher thermals vs. ATX builds.

- Q: Do Mini-ITX boards have fewer USB ports?

- A: Typically yes—most offer 6-8 rear USB ports vs. 10-12 on ATX. However, premium models like the NZXT N7 Z690 include front-panel USB-C expansion.

- Q: Are Mini-ITX builds louder than ATX?

- A: Often yes—compact cases require smaller, faster-spinning fans. Solutions like the Noctua NH-L9i cooler mitigate noise but add $50-70 to build costs.